Recycle in upflow anaerobic sludge blanket reactor on treatment

ORIGINAL PAPER

Recycle in up?ow anaerobic sludge blanket reactor on treatment of real textile dye ef?uent

G.Gnanapragasam ?M.Senthilkumar ?

V.Arutchelvan ?P.Sivarajan ?S.Nagarajan

Received:14October 2009/Accepted:2December 2009/Published online:20December 2009óSpringer Science+Business Media B.V.2009

Abstract The discharge of textile wastewater containing dye in the environment is varying for both toxicology and esthetical reasons as dyes impede light penetration,damage the quality of the receiving streams.Up?ow anaerobic sludge blanket reactor with anaerobic digester sludge treating starch wastewater has been used to investigate the removal ef?ciency of chemical oxygen demand (COD)and colour of textile dye wastewater.In this study,the starch and textile dye wastewater was mixed at 70and 30%,respectively,and the experiments were carried out with recycle of treated wastewater at different percentage as 10,20,30and 40.Maximum removal of COD and colour was 96%and 93.3%,respectively,at 30%recycle.At various OLR and HRT,the maximum removal of COD,colour was 95.9%,93%at 6.81kg COD/m 3d and 96%,93%with 24h of HRT.The maximum production of biogas at 24h of HRT with 30%recycle was about 355l/d.The Volatile fatty acid/Alkalinity ratio of methanogenic reactor was found to be 0.049–0.053.The result provided evidence,the starch and dye wastewater have wide variation in their characteristics was treated on combination,this new tech-nology supports the effective utilization of starch waste in destruction of dye.

Keywords Recycle ratio áColour removal áAcidogenic áMethanogenic áUASB

Introduction

Industrialization is vital to a nation’s economy because it serves as a vehicle for development.However,there are associated problems resulting from the introduction of industrial waste products into the environment.Textile industry,which is one the largest water consumer in the world,produces the ef?uents that contain several types of chemicals such as dispersants,leveling agents,acids,alkalis,carriers and various dyes (Cooper 1995).Colour is one of the most obvious indicators of water pollution and discharge of highly coloured synthetic dye ef?uents can be damaging the receiving water bodies (Nigam et al.1996).The release of coloured compounds into water bodies is undesirable not only because of their impact on photo-synthesis of aquatic plants but also due to the carcinogenic nature of many of these dyes and their break-down prod-ucts (Weisburger 2002).Therefore,it is necessary to treat completely these types of wastewater before releasing to environment.In addition,textile industry wastewater pre-sents the additional complexity of dealing with unknown quantities and varieties of many kinds of dyes,as well as low BOD/COD ratios,which may affect the ef?ciency of the biological decolourization.Physico-chemical treatment methods are the least desirable owing to their high costs and generation of secondary pollutants.On the other hand,biological treatment methods are attractive due to their cost effectiveness,diverse metabolic pathways and versatility of microorganisms (Banat et al.1996;Singh et al.2004;Mendez-Paz et al.2005;Van der Zee and Villaverde 2005;Pandey et al.2007).Among the anaerobic processes,

G.Gnanapragasam (&)áM.Senthilkumar áV.Arutchelvan áP.Sivarajan

Department of Civil Engineering,Annamalai University,Annamalainagar,Tamil Nadu 608002,India e-mail:gnanapragasam_g@yahoo.co.in;gunasekarangnanapragasam@https://www.sodocs.net/doc/2714037859.html, S.Nagarajan

Department of Chemistry,Annamalai University,Annamalainagar,Tamil Nadu 608002,India

World J Microbiol Biotechnol (2010)26:1093–1098DOI 10.1007/s11274-009-0275-0

Up?ow Anaerobic Sludge Blanket(UASB)reactor has been widely used to treat variety of industrial and domestic wastewaters all over the world.One common feature offered by all the high-rate processes is their ability to provide high Solid Retention Time(SRT)in relation to Hydraulic Retention Time(HRT).High biomass concen-tration is maintained in a reactor with relatively low treatment time.Generally more resistant to toxic com-pounds as the result of structure of formed granular sludge with good settling velocities and mechanical strength,and suitable for the treatment of wastewater containing xeno-biotic and recalcitrant compounds,and it promotes adap-tation of bacteria to the presence of toxic compounds,and as well as it can be used for treatment of wastewater pre-viously considered unsuitable for anaerobic treatment (Somasiri et al.2006).The aim of this study is to deco-lourize the real textile wastewater containing combined dye using starch industry ef?uent as co-substrate in hybrid bi-phasic UASB reactor with different ratios of recycling the ef?uent from methanogenic reactor.

Materials and methods

Biomass

The methanogenic granular sludge with unknown micro-

organisms used in this experiment was procured from the anaerobic digester treating tapioca starch ef?uent of M/s Perumal SAGO factory,Salem,Tamil Nadu,India.Before loading the reactor,granular sludge was clearly washed,?ltered through a?ne mesh to reduce all the inorganic mineral contents.The volatile suspended solids content of the sludge was then estimated about60,000mg/l(APHA-AWWA-WPCF2005).

Wastewater

The real untreated wastewater of starch industry and textile dye industry was collected from Sago factory and textile dyeing industry,Salem,Tamil Nadu,India.Totally ten wastewater samples were collected from each industries for duration of three months and the mean values of the parameters have been tabulated in Table1.The complete analysis of the wastewater was carried out according to standard methods APHA-AWWA-WPCF(2005).

Experimental setup

In order to study the operational and performance charac-teristics of UASB reactor,a hybrid bi-phasic Up?ow Anaerobic Sludge Blanket(UASB)reactor was fabricated. The acidogenic and methanogenic reactors are fabricated with1:4volumetric ratios.The?rst phase is an acidogenic reactor(300mm inner diameter and820mm height)was made up of plexi-glass with working volume of56l and second phase is a stainless steel methanogenic reactor (350mm inner diameter and2,400mm height)with working volume of230l.First the untreated real ef?uent was fed into the acidogenic reactor and secondly from acidogenic to the methanogenic reactor.Sampling ports were provided at a equal spacing of400mm from the bottom of the reactor to the top.On the top of the reactor, gas de?ection was attached.The Gas–Liquid-Solid Sepa-rator(GLSS)consisted of an inverted conical funnel at top of the water column for the collection of biogas.In addition to the GLSS arrangement,a packed medium consisting of a PVC spirals size of26mm,surface area500m2m-3and void ratio87%has been provided for a height of200mm locating at1,770mm from the bottom of the reactor.The spiral will retain the biomass in addition to giving polishing effect to the ef?uent.The sludge granules trapped in GLSS and the spiral will return to the reactor as soon as the gas entrapped inside the granules is released.Biogas generated was measured using wet gas?ow meter.After stabilizing the reactor,studies were conducted under the steady state conditions.At steady state of the bioreactor performance parameters like COD,pH,colour removal were relatively constant(\10%).The reactor was operated at ef?uent Table1Characteristics of wastewaters

S.No.Parameters a Textile dye ef?uent Sago ef?uent 1pH12.8 4.5

2Total suspended solids420.0640.0

3Total dissolved solids3,520.01,200.0

4Chlorides1,520.0400.0

5Sulphates180.0123.0

6BOD175.02,400.0

7COD1,600.06,000.0

a All values except pH are

mg/l

recycle mode.The in?uent feed of the reactor consists of 70%of real sago wastewater and30%of real textile dye ef?uent and operated at24h HRT.The treated ef?uent from methanogenic reactor was recycled at90:10,80:20, 70:30and60:40ratios(70/30mixing of sago and textile dye:recycle of methanogenic outlet).

Start-up phase

About50%of both acidogenic and methanogenic reactors were seeded with previously screened and washed digester sludge treating the starch ef?uents.The reactor was oper-ated at room temperature and the feed solution was led into the reactor at the required rate in an up?ow mode using a

Variable Speed Pump(Miclins VSP50).The initial COD of starch ef?uent was6,000mg/l organic loading rate (OLR)was1.44kg COD m-3d-1with hydraulic retention time(HRT)of24h.Ammonium chloride and potassium dihydrogen phosphate were added to maintain a COD:N:P (macro nutrients)ratio of300:10:1so as to maintain bal-anced nutrients in the feed for the growth of microorgan-isms.To improve settling characteristics trace amount of cobalt chloride,nickel chloride,zinc chloride,barium chloride and boron all of analytical grade were added (Lettinga et al.1985)once a week as suggested by Henze and Harremoes(1983).

Since the sludge activity was initially low,lower feed concentration helped to control excessive volatile fatty acid (VFA)formation and guarded against excessive pH drop. The COD conversion ef?ciencies as well as gas production showed remarkable improvement after third day.On the thirty-?rst day the reactor showed signs of stability.After stabilizing the reactor,studies were conducted under the steady state conditions.At steady state of the bioreactor performance parameters like COD,pH,colour removal were relatively constant(\10%).The reactor was operated at ef?uent recycle mode.The in?uent feed of the reactor was in the ratio of70%of real sago wastewater and30%of real textile dye ef?uent.The optimum mixing ratio of synthetic textile dye and starch wastewater in bench scale reactor was already found by Senthilkumar et al.(2009). The treated ef?uent from methanogenic reactor was recy-cled at90:10,80:20,70:30and60:40ratios(70/30mixing of sago and textile dye:recycle of methanogenic outlet). Result and discussion

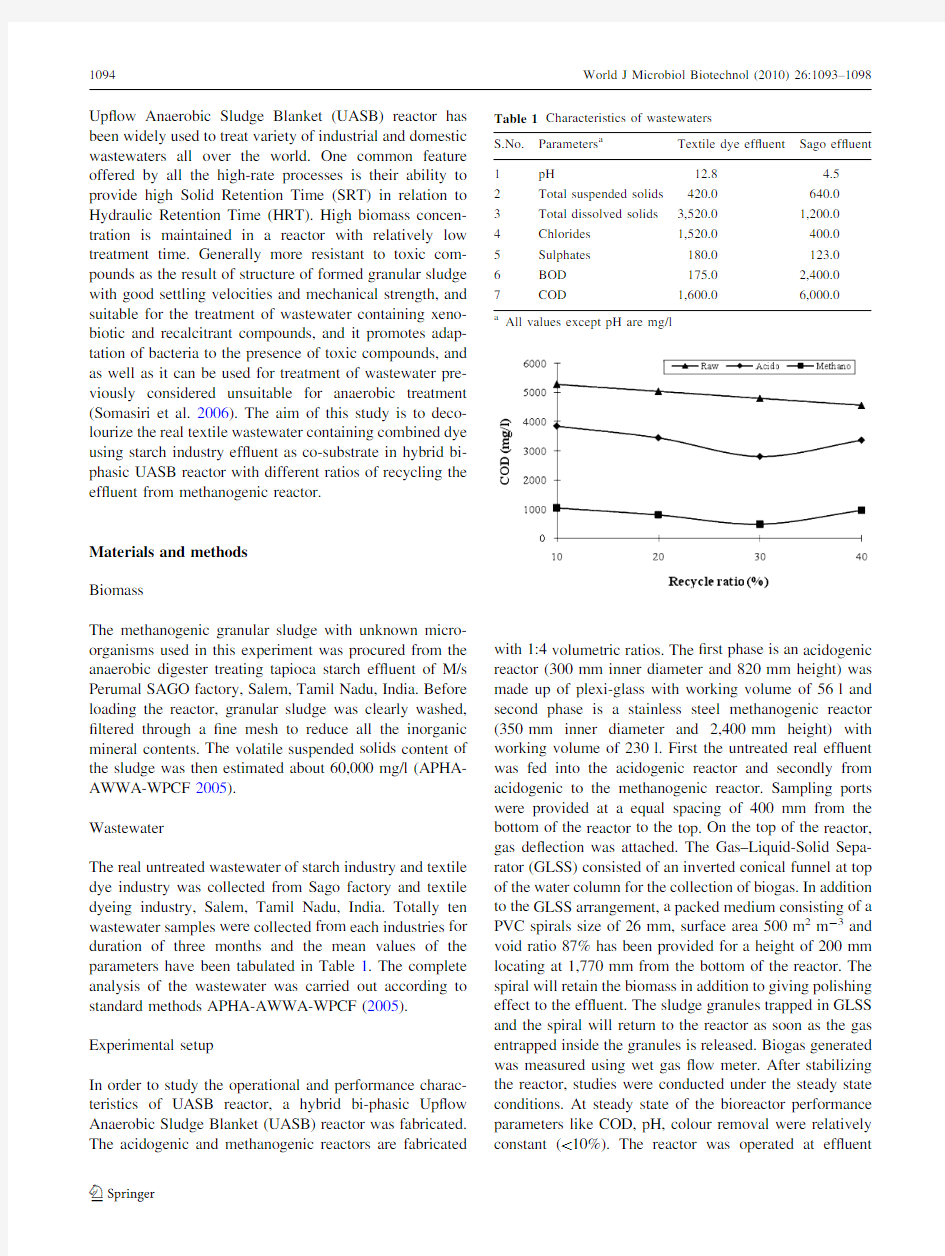

Effects of ef?uent recycle on COD removal

Figure1shows the COD concentrations of combined ef?uent of starch and textile dye with various recycling ratio of treated ef?uent.As the recycling ratio increases,the COD of inlet wastewater get decreased due to dilution of the feed.The reactor was fed with the COD range of 5,840–4,720mg/l.The COD removal ef?ciency at various recycling ratios is shown in Fig.2.There is a gradual increment of removal ef?ciency up to30%of recycling after that it becomes almost stable.Recirculation generally improves the performance of the reactor(Van der Zee and Villaverde2005).Ef?uent recycle will?uidize the sludge bed to have a suf?cient contact between wastewater and sludge even at low organic loads and certainly will result in high treatment ef?ciency(Lettinga et al.1985).As quoted by Van den Berg et al.(1981)and Lettinga et al.(1985) 96.7%of COD removal ef?ciency was achieved by30%of recycling the ef?uent.The removal ef?ciencies of COD in acidogenic and methanogenic reactors are in the range of 28–43%and79–96%,respectively(Fig.2).The overall COD removal ef?ciency of30%recycling was about 96.6%at HRT of24h.A maximum COD removal at a mixing ratio of60%of synthetic starch wastewater and 40%of synthetic dye using bench scale reactor without recycle was about96%(Senthilkumar et al.2009).It is also evident that30%of ef?uent recycle is the most optimum level(Fig.2).

Effects of ef?uent recycle on color removal

The intensity of colour in the in?uent and outlets of aci-dogenic and methanogenic reactors were measured using UV-Vis Spectrometer at600nm was shown in Fig.3.The optical density values of different recycle ratio for feed vary between0.412and0.652.Figure4shows the removal ef?ciencies of colour in acidogenic and methanogenic reactor.The colour removal ef?ciency was in the range of 71–93.3%at24h HRT for various ratios of ef?uent recycle.Chinwetkitvanich et al.2000disclosed that the colour removal ef?ciency from three different real waste-waters was in the range of36–71%,whereas,from syn-thetic wastewaters between56and63%with synthetic tapioca starch as co-substrate in both the experiments

using

two-stage UASB reactor of3l capacity in12h HRT.In this study,the colour removal ef?ciency from real dye bath wastewater was about93.3%with real sago ef?uent as co-substrate using hybrid UASB reactor system of230l capacity in24h HRT.

In?uence of pH

Methanogenic microorganisms are more susceptible to even a minute changes in the pH values.The pH values of raw ef?uent,acidogenic and methanogenic reactor ef?uent for various recycle ratios at24h of HRT are shown in Fig.5.In?uent pH values ranges between 6.3for no recycle and6.5for ef?uent recycle,whereas,the pH values were vary optimum ranges of6.8–8.0for both stage of reactors.Speci?cally for methanogenic reactor ef?uent pH increased and remained between7.8and8.0.Optimum pH ranges of6.0–7.2,6.4–7.2,and6.6–7.6have been reported to be favorable for the methane bacteria,which cannot tolerate the?uctuations(Cheremisinoff and Morress1976; Dugan1977;Jayantha and Ramanujam1996).The pH maintained inside the reactor,due to the process results from the interaction of the carbon dioxide-bicarbonate buffering system and volatile acids-ammonia formed by the process(Bisselli1975).It is necessary to prevent the accumulation of acids,to a level,which may become inhibitory to the methane bacteria.In this study,suf?cient buffering was present in the reactor,which prevents the reactor souring.

In?uence of volatile fatty acid(VFA)/Alkalinity ratio Figure6shows the volatile fatty acid(VFA)/Alkalinity ratio for both acidogenic and methanogenic reactors for different percentage of ef?uent recycle at24h of HRT. The ef?uent volatile fatty acid(VFA)/Alkalinity ratio of the acidogenic reactor was more or less equal to1which demonstrates the proper functioning of acidogenic species in the anaerobic process.Similarly,the volatile fatty acid (VFA)/Alkalinity ratio of methanogenic reactor ranges between0.049and0.053.It reveals that throughout the experimental period volatile fatty acid accumulation was under control and the reactor was under stable condition.In a stable reactor,volatile fatty acid content will be low in proportion to the available alkalinity.Simpson(1960) reported that the volatile fatty acid(VFA)/Alkalinity ratio must be very low range for stable anaerobic digester.Even though a little accumulation of volatile fatty acid was observed in increased dye concentrations,the

detected

values of volatile fatty acid,alkalinity and pH showed that the values are in the range of desirable limits of anaerobic process(Somasiri et al.2008).

Effect of organic loading rate(OLR)

Figures7and8illustrates the percentage removal ef?-ciency of COD and colours at different organic loading rates with30%of ef?uent recycle.The various OLRs are 3.36,4.09,5.04and6.81kg COD/m3d for36,30,24and 18h HRTs,respectively,with an Up?ow velocity of 0.1m/h.The COD and colour removal ef?ciencies in the methanogenic reactor were found to be higher of about 95.9and93%,respectively,at an OLR of6.81kg COD/ m3d.Similarly,the COD and colour removal ef?ciencies in the acidogenic reactor were found to be38.9and45.6%, respectively.Talarposhti et al.(2000)reported a maximum colour removal of90%at OLR of0.25kg COD/m3.d with an HRT of?ve days in two-stage anaerobic packed bed reactor.Torkian et al.(2004)achieved85%of COD removal with an Up?ow velocity of0.9–1m/h and organic loading rates of14–25kg COD/m3d.In?uence of hydraulic retention time(HRT)

Figures9and10shows HRT versus COD and colour removal at various HRTs such as36,30,24and18h.The COD removal in acidogenic reactor was in the range of 27–38%and in methanogenic reactor was82–96%at dif-ferent HRT for30%ef?uent recycling.The maximum removal ef?ciency of COD was achieved at24h HRT.The colour removal ef?ciency for both acidogenic and metha-nogenic reactor was in the range of32–46%and83–93%, respectively.Senthilkumar et al.(2009)had reported that COD and colour removal ef?ciency was found to be maximum at12h HRT in bench scale study using syn-thetic wastewaters.

Biogas production

The biogas production at various percentage of ef?uent recycles at24h HRT was shown in Fig.11.The biogas generation was decreased with increase of dye wastewater. The maximum production of biogas was measured about 355l/d for30%ef?uent recycle,whereas,the biogas pro-duction at10,20,and40%was recorded as158,284

and

324l/d,respectively.Biogas production is directly related to COD stabilization,for example without biogas produc-tion minimal COD removal occurs(Gardy et al.1999). Mustafa Isik(2004)reported the maximum biogas pro-duction of180ml/day when the COD was2,026mg/l. Conclusion

Textile industry wastewaters are degraded and decolorized using starch industry wastewater as co-substrate in two-phase up?ow anaerobic sludge blanket reactor.An ef?uent recycle ratio of30%of methanogenic outlet was opti-mized.Overall COD and colour removal ef?ciency of96 and93%,respectively.The reactor was operated at several HRTs(36,30,24and18)and maximum COD and colour removal were obtained at24h HRT.The VFA/Alkalinity ratio was in the range of stable condition for the anaerobic reactors.The biogas production was355l/d at optimized condition.The two-phase pilot plant UASB reactor pro-duces much less organic sludge comparable with present conventional physico-chemical treatment systems. Acknowledgments One of the Authors(V.Arutchelvan)is thankful to the University Grants Commission(UGC),New Delhi,India,for their?nancial assistance through major research project.

References

APHA-AWWA-WPCF(2005)Standard methods for the examination of water and waste water,19th edn.American Public Health Association,Washington

Banat IM,Nigam P,Singh D,Marchant R(1996)Microbial decolorization of textile dye-containing ef?uents:a review.

Bioresour Technol58:217–227

Bisselli C(1975)Anaerobic treatment process stability,Urban Trash Methanation-Background for a proof of concept Experiment NSF RA-N-75–002.Mitre Corporation,McLean Cheremisinoff PN,Morress AC(1976)Energy from solid wastes.

Marckel Dekker,New York

Chinwetkitvanich S,Tuntoolvest M,Panswad T(2000)Anaerobic decolorisation of reactive dye bath ef?uents by two-stage UASB system with tapioca as a co-substrate.Water Res34(8):2223–2232

Cooper P(1995)Color in dyehouse ef?uent.Society of dyers and colourists,Bradford

Dugan PR(1977)Biochemical ecology of water pollution.Plenum Press,New York

Henze M,Harremoes P(1983)Anaerobic treatment of wastewater in ?xed?lm reactors–literature review.Water Sci Technol15(8/

9):1–101IAWPRC,Pergramon press https://www.sodocs.net/doc/2714037859.html,

Jayantha KS,Ramanujam TK(1996)Biomethanation from waste-water using up?ow anaerobic sludge blanket(UASB)process.

Indian J Environ Health38:171–180

Lettinga G,Zeeuw de W,Hulshoff P,Wiegant W,Rinzema A(1985) Anaerobic wastewater treatment based on biomass retention with emphasis on the UASB-process.In:Proceedings of the4th international symposium on anaerobic digestion held in Guangzhou,China

Mendez-Paz D,Omil F,Lema JM(2005)Anaerobic treatment of azo dye acid orange7under fed-batch and continuous conditions.

Water Res39:771–778

Nigam P,Banat IM,Singh D,Marchant R(1996)Microbial process for the decolourization of textile ef?uent containing azo,diazo and reactive dyes.Process Biochem31:435–442

Pandey A,Singh P,Iyengar L(2007)Bacterial decolourisation and degradation of azo dyes.Int Biodeterior Biodegradation59:73–84

Senthilkumar M,Arutchelvan V,Kanakasabai V,Venkatesh KR (2009)Biomineralisation of dye waste in a two-phase hybrid UASB reactor using starch ef?uent as a co-substrate.Int J Environ Waste Manag3:354–365

Simpson JR(1960)Some aspects of bio-chemistry of anaerobic digestion in wastewater treatment.In:Issac PCG(ed)Waste treatment.Pub Pergamon Press,Oxfoard,pp31–51

Singh P,Mishra LC,Iyengar L(2004)Biodegradation of4-amin-obenzenesulphonate by newly isolated bacterial strain PNS-1.

World J Microbiol Biotechnol20:845–849

Somasiri W,Ruan W,Xiufen L,Jian C(2006)Decolourization of textile wastewater containing acid dyes in UASB reactor system under mixed anaerobic granular sludge.Electron Environ Agric Food Chem5:1224–1234

Somasiri W,Ruan W,Xiufen L,Jian C(2008)Colour and cod removal,reactor performance,and stability in textile wastewater treatment by up?ow anaerobic sludge blanket reactor at meso-philic temperature.Electron Environ Agric Food Chem7:3461–3475

Talarposhti AM,Donnelly T,Anderson GK(2000)Colour removal from a stimulated dye wastewater using a two-phase anaerobic packed bed reactor.Water Res35:425–432

Torkian A,Amin MM,Kermanshahi RK,Salehi MS(2004) Granulation in UASB system treating slaughterhouse wastewa-ter.Sci Food Agric53:175–184

Van den Berg L,Kennedy KJ,Hamoda MF(1981)Effect of type of waste on performance of anaerobic?xed?lm and up?ow sludge bed reactors.In:Proceedings of36th Purdue Indust.Waste Conf.,pp686–692

Van der Zee FP,Villaverde S(2005)Combined anaerobic-aerobic treatment of azo dyes—a short review of bioreactor studies.

Water Res39:1425–1440

Weisburger JH(2002)Comments on the history and importance of aromatic and heterocyclic amines in public health.Mutat Res

506(507):9–20