ASTM A487-93(98)

D

1This speci?cation is under the jurisdiction of ASTM Committee A-1on Steel, Stainless Steel,and Related Alloysand is the direct responsibility of Subcommittee A01.18on Castings.

Current edition approved Dec.15,1993.Published April1994.Originally published as A487–https://www.sodocs.net/doc/4a2709059.html,st previous edition A487/A487M–91.

2For ASME Boiler and Pressure Vessel Code applications see related Speci?-cations SA-487in Section II of that code.

3Annual Book of ASTM Standards,V ol01.03.

4Annual Book of ASTM Standards,V ol01.02.

5Annual Book of ASTM Standards,V ol03.03.

6Available from American Society of Mechanical Engineers,345E.47th St., New York,NY10017.

7Available from Manufacturer’s Standardization Society of the Valve and Fittings Industry,127Park St.,N.E.Vienna,V A22180.

1

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100Barr Harbor Dr.,West Conshohocken,PA19428 Reprinted from the Annual Book of ASTM Standards.Copyright ASTM

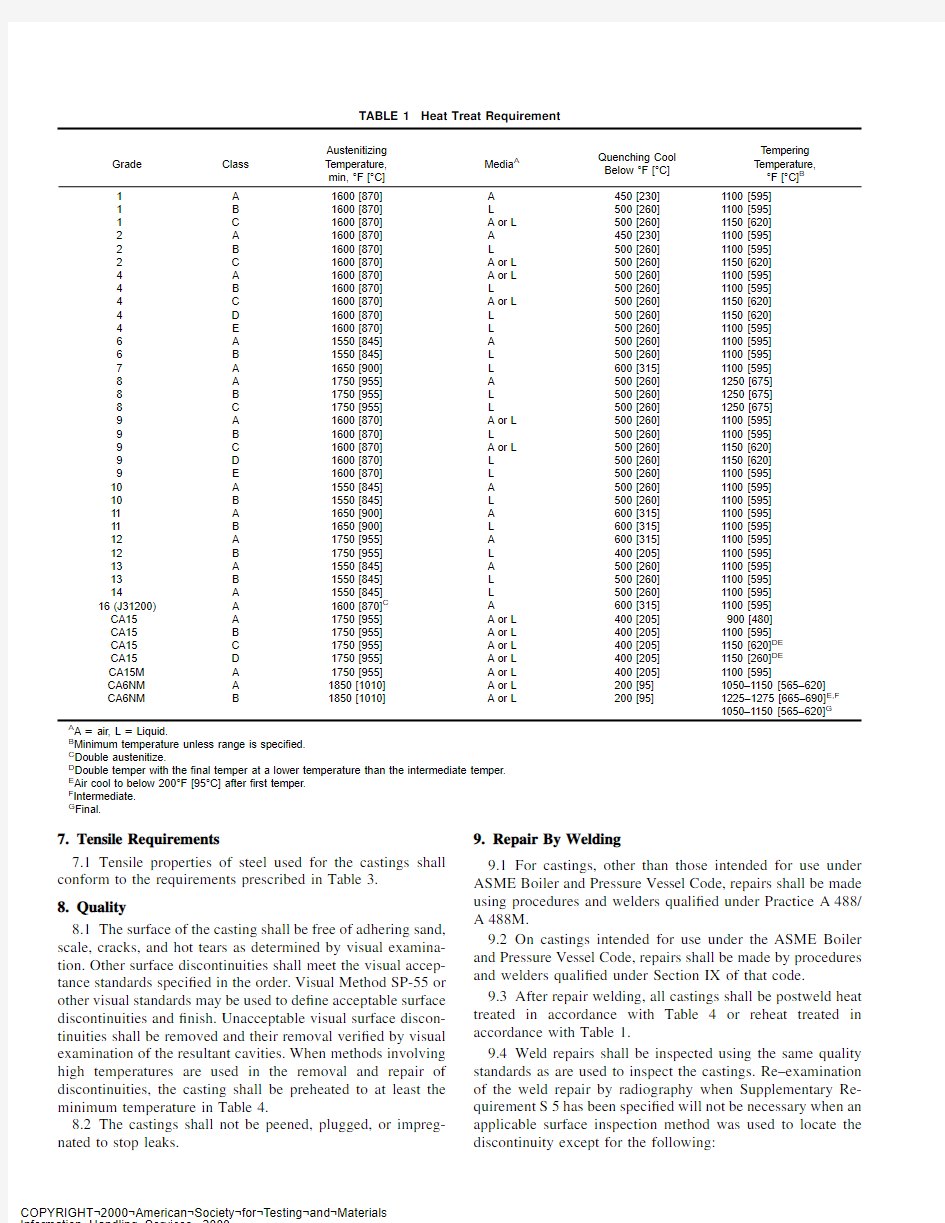

7.Tensile Requirements

7.1Tensile properties of steel used for the castings shall conform to the requirements prescribed in Table 3.

8.Quality

8.1The surface of the casting shall be free of adhering sand,scale,cracks,and hot tears as determined by visual examina-tion.Other surface discontinuities shall meet the visual accep-tance standards speci?ed in the order.Visual Method SP-55or other visual standards may be used to de?ne acceptable surface discontinuities and ?nish.Unacceptable visual surface discon-tinuities shall be removed and their removal veri?ed by visual examination of the resultant cavities.When methods involving high temperatures are used in the removal and repair of discontinuities,the casting shall be preheated to at least the minimum temperature in Table 4.

8.2The castings shall not be peened,plugged,or impreg-nated to stop leaks.

9.Repair By Welding

9.1For castings,other than those intended for use under ASME Boiler and Pressure Vessel Code,repairs shall be made using procedures and welders quali?ed under Practice A 488/A 488M.

9.2On castings intended for use under the ASME Boiler and Pressure Vessel Code,repairs shall be made by procedures and welders quali?ed under Section IX of that code.

9.3After repair welding,all castings shall be postweld heat treated in accordance with Table 4or reheat treated in accordance with Table 1.

9.4Weld repairs shall be inspected using the same quality standards as are used to inspect the castings.Re–examination of the weld repair by radiography when Supplementary Re-quirement S 5has been speci?ed will not be necessary when an applicable surface inspection method was used to locate the discontinuity except for the following:

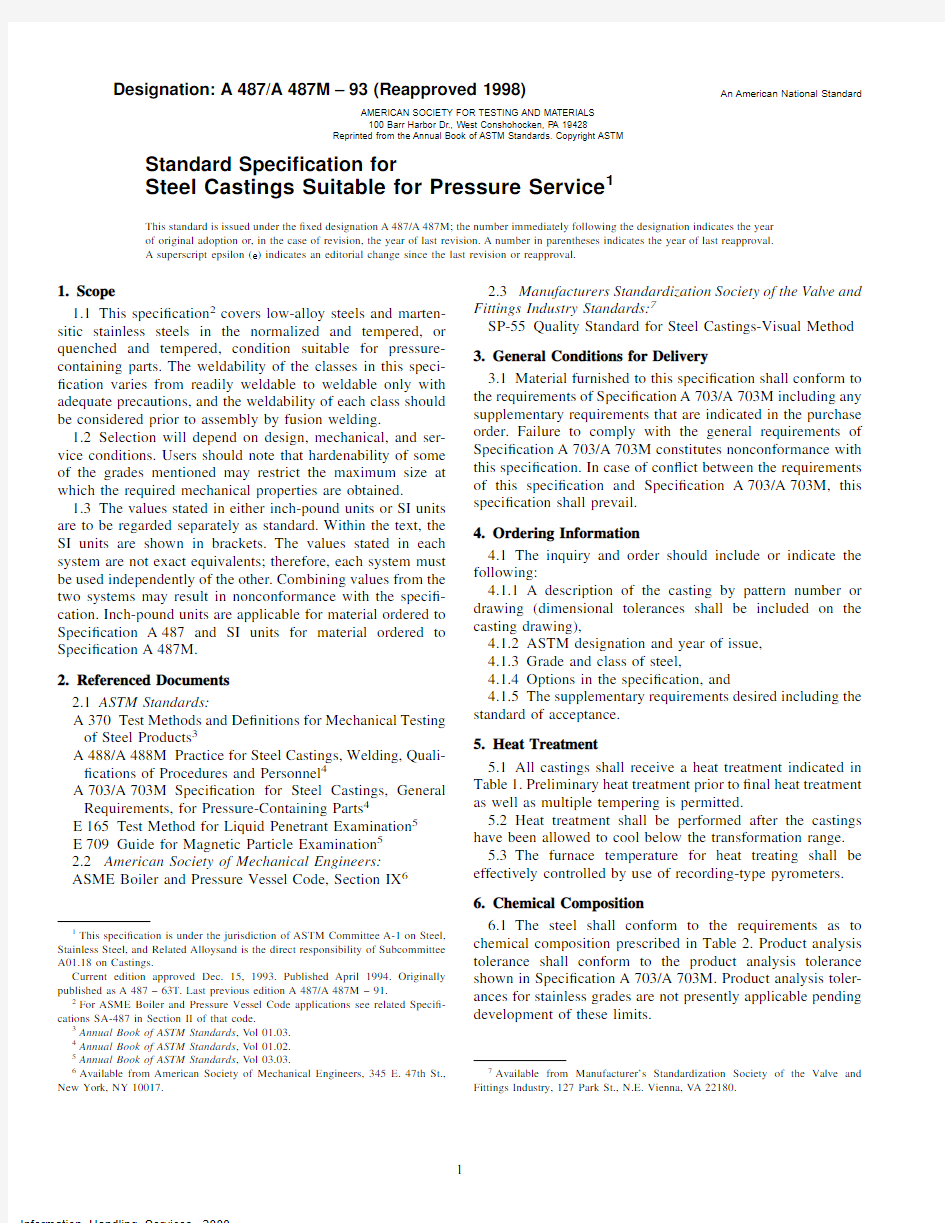

TABLE 1Heat Treat Requirement

Grade Class Austenitizing Temperature,min,°F [°C]Media A Quenching Cool Below °F [°C]Tempering Temperature,°F [°C]B

1A 1600[870]A 450[230]1100[595]1B 1600[870]L 500[260]1100[595]1C 1600[870]A or L

500[260]1150[620]2A 1600[870]A 450[230]1100[595]2B 1600[870]L 500[260]1100[595]2C 1600[870]A or L 500[260]1150[620]4A 1600[870]A or L 500[260]1100[595]4B 1600[870]L 500[260]1100[595]4C 1600[870]A or L

500[260]1150[620]4D 1600[870]L 500[260]1150[620]4E 1600[870]L 500[260]1100[595]6A 1550[845]A 500[260]1100[595]6B 1550[845]L 500[260]1100[595]7A 1650[900]L 600[315]1100[595]8A 1750[955]A 500[260]1250[675]8B 1750[955]L 500[260]1250[675]8C 1750[955]L 500[260]1250[675]9A 1600[870]A or L 500[260]1100[595]9B 1600[870]L 500[260]1100[595]9C 1600[870]A or L

500[260]1150[620]9D 1600[870]L 500[260]1150[620]9E 1600[870]L 500[260]1100[595]10A 1550[845]A 500[260]1100[595]10B 1550[845]L 500[260]1100[595]11A 1650[900]A 600[315]1100[595]11B 1650[900]L 600[315]1100[595]12A 1750[955]A 600[315]1100[595]12B 1750[955]L 400[205]1100[595]13A 1550[845]A 500[260]1100[595]13B 1550[845]L 500[260]1100[595]14

A 1550[845]L 500[260]1100[595]16(J31200)A 1600[870]C A 600[315]1100[595]CA15A 1750[955]A or L 400[205]900[480]CA15

B 1750[955]A or L 400[205]1100[595]CA15

C 1750[955]A or L 400[205]1150[620]DE CA15

D 1750[955]A or L 400[205]1150[260]D

E CA15M A 1750[955]A or L 400[205]1100[595]

CA6NM A 1850[1010]A or L 200[95]1050–1150[565–620]CA6NM

B

1850[1010]

A or

L

200

[95]

1225–1275[665–690]E ,F 1050–1150[565–620]G

A

A 5air,L 5Liquid.

B

Minimum temperature unless range is speci?ed.C

Double austenitize.D

Double temper with the ?nal temper at a

lower temperature than the intermediate temper.E

Air cool to below 200°F [95°C]after ?rst temper.F

Intermediate.G

Final.

9.4.1Weld repairs on castings which have leaked on hydro-static test.

9.4.2Weld repairs on castings in which the depth of any cavity prepared for repair welding is more than 20%of the wall thickness or 1in.[25mm],whichever is smaller.

9.4.3Weld repairs on castings in which any cavity prepared for welding is greater than approximately 10in.2[65cm 2].

10.Product Marking

10.1Castings shall be marked for material identi?cation with the grade and class symbols (1-A,4-C,CA15-A).11.Keywords

11.1steel castings;alloy steel;stainless steel;martensitic stainless steel;pressure containing parts

TABLE 2Chemical Requirements (Maximum Percent Unless Range is Given)

Grade

1.

2.

4.

6.

7.

8.

9.

10.11.

12.

Class Type ABC Vanadium

ABC Manganese-Molyb-denum ABCDE Nickel-Chromium-Molybdenum

AB Manganese Nickel-Chromium-Molybdenum A Nickel-Chromium-Molybdenum-Vanadium A ABC Chromium-Molyb-denum ABCDE Chromium-Molyb-denum AB Nickel-Chromium-Molybde-num AB Nickel-Chromium-Molybdenum AB Nickel-Chromium-Molybdenum

Carbon 0.300.30

0.300.05–0.380.05–0.200.05–0.200.05–0.330.30

0.05–0.200.05–0.20Manganese 1.00 1.00–1.40 1.00 1.30–1.700.60–1.000.50–0.900.60–1.000.60to 1.000.50–0.800.40–0.70Phosphorus 0.040.040.040.040.040.040.040.040.040.04Sulfur 0.0450.0450.0450.0450.0450.0450.0450.0450.0450.045Silicon 0.800.800.80

0.80

0.80

0.800.800.80

0.60

0.60

Nickel ......0.40–0.800.40–0.800.70–1.00...

...

1.40–

2.000.70–1.100.60–1.00Chromium ......

0.40–0.800.40–0.800.40–0.80 2.00–2.750.75–1.100.55–0.900.50–0.800.50–0.90Molybdenum ...

0.10–0.300.15–0.300.30–0.400.40–0.600.90–1.100.15–0.300.20–0.400.45–0.650.90–1.20Vanadium 0.04–0.12.........0.03–0.10...............Boron ............0.002–0.006...............Copper

............0.15–0.50...............Residual Elements:Copper 0.500.500.500.500.500.500.500.500.500.50Nickel 0.500.50............0.50.........Chromium 0.350.35........................Mo +W 0.25...........................Tungsten ...0.100.100.100.100.100.100.100.100.10Vanadium

...0.030.030.03...0.030.030.030.030.03Total content of residual elements

1.00

1.00

0.60

0.60

0.60

0.60

1.00

0.60

0.50

0.50

Grade

13.14.16CA15CA15M CA6NM

Class Type

AB Nickel-Molybdenum A Nickel-Molybdenum A

Low Carbon Manganese-Nickel (J31200)ABCD Martensitic Chromium A

Martensitic Chromium

AB Martensitic Chromium Nickel

Carbon 0.30

0.55

0.12B 0.150.150.06Manganese 0.80–1.100.80–1.10 2.10B 1.00 1.00 1.00Phosphorus 0.040.040.020.0400.0400.04Sulfur 0.0450.0450.020.0400.0400.03Silicon 0.60

0.60

0.50

1.500.65 1.00Nickel 1.40–1.75 1.40–1.75 1.00–1.40 1.00

1.0

3.5–

4.5Chromium ...

...

...11.5–14.011.5–14.011.5–14.0Molybdenum 0.20–0.300.20–0.30...0.500.15–1.00.4–1.0Boron ..................Copper

..................Residual Elements Copper 0.500.500.200.500.500.50Nickel ..................Chromium 0.400.400.20.........Molybdenum ......0.10.........Tungsten 0.100.100.100.100.100.10Vanadium

0.030.030.020.050.050.05Total content of residual elements

0.75

0.75

0.50

0.50

0.50

0.50

A Proprietary steel composition.

B

For each reduction of 0.01%below the speci?ed maximum carbon content,an increase of 0.04%manganese above the speci?ed maximum will be permitted up to a maximum of 2.30

%.

TABLE3Required Mechanical Properties

Previous Designation Grade Class

Tensile Strength,A

min,ksi[MPa]

Yield Strength,

min,ksi[MPa],

at0.2%Offset

Elongation,2in.

[50mm]or4d,

min,%

Reduction

of Area,

min%

Hardness

max,HRC

[HB]

Max

Thickness,

in.[mm]

1N1A85[585]–110[760]55[380]2240

1Q1B90[620]–115[795]65[450]2245

1C90[620]65[450]224522[235]

2N2A85[585]–110[760]53[365]2235

2Q2B90[620]–115[795]65[450]2240

2C90[620]65[450]224022[235]

4N4A90[620]–115[795]60[415]1840

4Q4B105[725]–130[895]85[585]1735

4C90[620]60[415]183522[235]

4D100[690]75[515]173522[235]

4QA4E115[795]95[655]1535

6N6A115[795]80[550]1830

6Q6B120[825]95[655]1225

7Q7A115[795]100[690]1530 2.5[63.5]

8N8A85[585]–110[760]55[380]2035

8Q8B105[725]85[585]1730

8C100[690]75[515]173522[235]

9N9A90[620]60[415]1835

9Q9B105[725]85[585]1635

9C90[620]60[415]183522[235]

9D100[690]75[515]173522[235]

9E115[795]95[655]1535

10N10A100[690]70[485]1835

10Q10B125[860]100[690]1535

11N11A70[484]–95[655]40[275]2035

11Q11B105[725]–130[895]85[585]1735

12N12A70[485]–95[655]40[275]2035

12Q12B105[725]–130[895]85[585]1735

13N13A90[620]–115[795]60[415]1835

13Q13B105[725]–130[895]85[585]1735

14Q14A120[825]–145[1000]95[655]1430

16N16(J31200)A70[485]–95[655]40[275]2235

CA15A CA15A140[965]–170[1170]110[760]–130[895]1025

CA15CA15B90[620]–115[795]65[450]1830

CA15C90[620]60[415]183522[235]

CA15D100[690]75[515]173522[235]

CA15M CA15M A90[620]–115[795]65[450]1830

CA6NM CA6NM A110[760]–135[930]80[550]1535

CA6NM CA6NM B100[690]75[515]173523[255]B

A Minimum ksi,unless range is given.

B Test Methods and De?nitions A370,Table3a does not apply to CA6NM.The conversion given is based on CA6NM test coupons.(For example,see ASTM STP756.8)

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements shall not apply unless speci?ed in the purchase order.

A list of standardized supplementary requirements for use at the option of the purchaser is included in Speci?cation A703/A703M.Those which are ordinarily considered suitable for use with this speci?cation are given below.Others enumerated in Speci?cation A703/A

S1.Unspeci?ed Elements

S4.Magnetic Particle Inspection

S5.Radiographic Inspection

S8.Charpy Impact Test

S8.1In addition to the requirements listed in S8of Speci-?cation A703/A703M,the following speci?c requirements apply to this speci?cation:

S8.1.1When S8is speci?ed for Grades1B,2B,4B,6B, 7A,8B,9B,or10B,impact properties shall be determined by performing a Charpy V-notch impact test at?50°F[?46°C] with a speci?c minimum average value of15ft-lb[20J]and a speci?ed minimum single value of10ft-lb[14J].Other temperatures may be used upon agreement between the manu-facturer and the purchaser,in which case S8.1.3shall apply. Other higher speci?ed minimum average and single values may be used upon agreement between the manufacturer and the purchaser.

S8.1.2Impact requirements for grades other than1B,2B, 4B,6B,7A,8B,9B,and10B shall be agreed upon between the manufacturer and the purchaser.

S8.1.3When an impact test temperature other than?50°F [?46°C]is used for those grades listed in S8.1.1,the lowest test temperature at which the material meets the impact requirements shall be stamped with low stress stamps imme-diately ahead of the material symbol on the raised pad(for example,2510B for+25°F[?4°C]and02510B for?25°F [?32°C]).

S10.Examination of Weld Preparation

S10.1The method of performing the magnetic particle or liquid penetrant test shall be in accordance with Practice E709 or Practice E165.

TABLE4Minimum Pre-Heat and Post Weld Heat Treat Requirements

Grade Class

Minimum Pre-Heat

Temperature,°F[°C]

Post Weld Heat Treat,°F[°C]

1A,B200[95]1100[595]A minimum

1C200[95]1150[620]A minimum

2A,B200[95]1100[595]A minimum

2C200[95]1150[620]A minimum

4A,B,E200[95]1100[595]A minimum

4C,D200[95]1150[620]A minimum

6A,B300[150]1100[595]A minimum

7A300[150]1100[595]A minimum

8A,B,C300[150]1250[675]A minimum

9A,B,E300[150]1100[595]A minimum

9C,D300[150]1150[620]A minimum

10A,B300[150]1100[595]A minimum

11A,B300[150]1100[595]A minimum

12A,B300[150]1100[595]A minimum

13A,B400[205]1100[595]A minimum

14A400[205]1100[595]A minimum

16(J31200)A50[10]1100[595]A minimum

CA15A400[205]1750[955]air cool or liquid quench below400°F[205°C]temper at900°F[480°C]minimum CA15B400[205]1100[595]A minimum

CA15C,D400[205]1150[620]A minimum

CA15M A400[205]1100[595]A minimum

CA6NM A50[10]Final temper between1050[565]and1150[620]

CA6NM B50[10]Intermediate PWHT between1225[665]and1275[690]

Final temper PWHT1050[565]and1150[620]B

A Post weld heat treat temperature must be at or below the?nal tempering temperature.

B The intermediate and?nal PWHT temperatures shall be the same as the intermediate and?nal tempering temperatures,respectively,as the original heat treatment

of the castings.Cool to below200°F[95°C]between the intermediate and?nal PWHT.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this https://www.sodocs.net/doc/4a2709059.html,ers of this standard are expressly advised that determination of the validity of any such patent rights,and the risk of infringement of such rights,are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every?ve years and if not revised,either reapproved or withdrawn.Your comments are invited either for revision of this standard or for additional standards and should be addressed to ASTM Headquarters.Your comments will receive careful consideration at a meeting of the responsible technical committee,which you may attend.If you feel that your comments have not received a fair hearing you should make your views known to the ASTM Committee on Standards,100Barr Harbor Drive,West Conshohocken,PA19428.